What is carbon powder pollution in brush electric screwdriver?

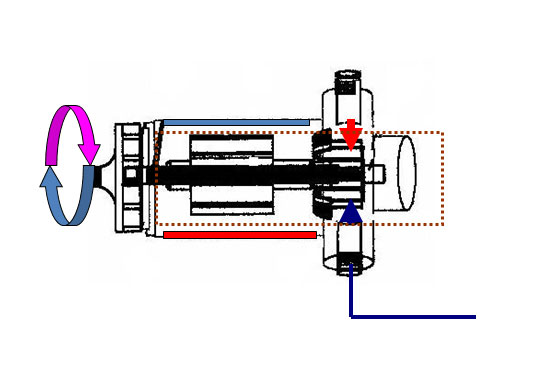

Brush electric screwdriver, brushed DC electric motor is used in this motor carbon brushes are used. The function of carbon brushes is to collect current from the commutator & supply it to the external load circuit (the armature of the machine being connected to the external load circuit via the commutator and brushes). The shape of carbon is rectangular and rest on the commutator of the DC motor. These carbon brushes are rubbing in commutator during the operation and covert in powder form, this carbon powder available in housing of the electric screwdriver and known as carbon powder pollution. Controlling of the brush electric screwdriver is done by mechanical switches because carbon powder can damage the electronics switches.

Advantage of using brushless Microntech KILEWS electric screwdriver –

Microntech KILEWS developed automatic industrial brushless electric screwdriver series. Brushless screwdrivers are compact, lightweight, ergonomically designed, and easy to use, less noise, environment friendly with dust free operation. Brushless motors have a particularly long operating life with no need for continue maintenance or replacement of expendable parts (carbon brushes, rotor, switches and other contact points).

Brushless screwdriver doesn’t have any carbon pollution so it can apply in clean room operation. Controlling switches like start and forward/reverse switches, these are sensor-based switches which are contactless and more durable than mechanical switches. All signal controlled by PCB and these signals could be accessed by the PLC. No wearing and noise problem, motor heat is also low only 40% of brush motor.

| Difference between Brush and brushless screwdriver- | ||

|---|---|---|

| Subject | Brush | Brushless |

| Pollution | Carbon Pollution because of carbon brush | No carbon pollution because of brushless motor |

| Noise | Noise level is high due to rubbing of brushes on commutator | Noise level is very low because of no rubbing of carbon brush on commutator |

| Motor | Less durable because of overheating due to rubbing brush | High durability because of no heating |

| Electric interference | Due to rubbing of carbon brush on commutator which results sparking | No electric interference |

| Torque | Unstable torque due to uneven current passes through carbon brush | Stable torque due to even current passes through PCB |

Microntech is partner of KILEWS assembling tools in India, which provides the best results to its customers in sense of quality and accuracy with his services. Microntech has presence everywhere in India and is the most preferred supplier for several manufacturers in India. To know more about fastening solutions provided by Microntech please visit our website www.microntechgroup.com and you can contact your nearest Microntech branch by mailing at sales@microntechgroup.com to schedule a demo or a visit for any issues you’re facing on your production line.