Why production volume and number of screw tightening per minute, an important data in selecting right tool for application in Microntech KILEWS tools

For any assembling line important data for tightening the application is time, because all manufacturing company have predefined target for production. And according to the production volume manufacturing company calculate the screw tightening time and takt time (Takt time of any assembly line is an expression of your customer demand normalized and leveled over the time you select to supply, within the production line total production or rate of production during a given time is named the takt time), so according to this data they select the screwdriver. If any application have 3 no. Of screw and the average time between start tightening and complete this unit is 1 minute, in this case per screw tightening time is approx. 20 second, so for this application you have to select high speed too from Microntech Kilews electric screwdriver series.

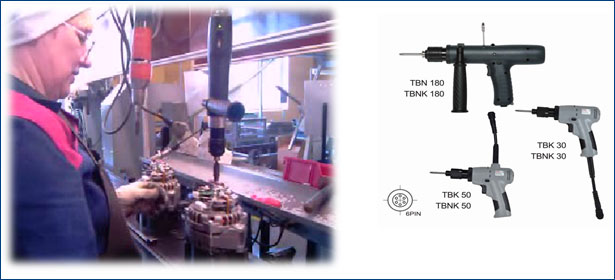

Microntech KILEWS developed industrial brushed and brushless electric screwdriver series. KILEWS screwdrivers are compact, light weight, ergonomically designed, and easy to use, less noise, environment friendly with dust free operation. Heat generated by the motor is reduced and screwdriver performance is usually at the utmost level leading to reliable product quality. KILEWS electric screwdriver ensures product quality, cost savings and a discount in overall failures. If you are interested in implementation of industrial-grade, KILEWS electric screwdrivers with smart tightening technology, high-precision screwdriver is just perfect for you. KILEWS clutch Shut-off electric screwdriver is available upto50 Nm, in clutch type electric screwdriver only KILEWS have this wide torque range 0.08 to 50 Nm.

Microntech KILEWS have high speed screwdrivers (SKD-RBK series), these screwdrivers are suitable for assembling large-scale work pieces in semi-automatic or full automatic production line. Especially, the foremost suitable for applications like automotive industrial parts assembly, electricity, telecommunications, large appliances and medical equipment assembly. These high speed models with twice the speed of Pneumatic screwdrivers, Noise free and ergonomic operation, OK/NG signals available and line integration are often done. Error detection like cross thread, double hit etc.

Microntech is a channel partner of KILEWS assembling tools in India, which provides the best results to its customers in sense of quality and accuracy with his services. Microntech has presence everywhere in India and is a preferred supplier for several manufacturers in India. To know more about assembly solutions provided by Microntech please visit our website www.microntechgroup.com otherwise you can contact your nearest Microntech branch by mailing at sales@microntechgroup.com to schedule a demo or a visit for any issues you’re facing on your production line.